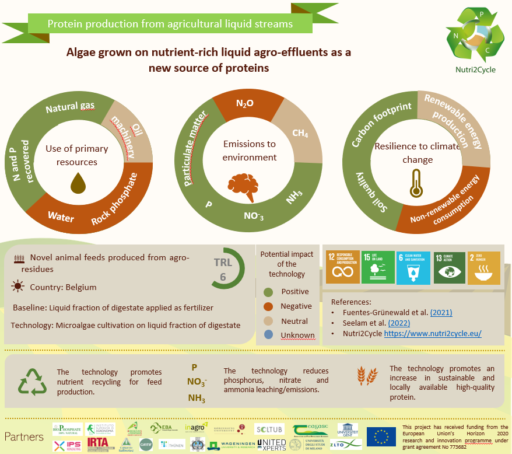

14. Algae grown on liquid agro-residues as a new source of proteins

RL5: Novel animal feeds produced from agro-residue

Responsible partner: Ghent University

Country: Ghent, BELGIUM

TRL and Scale of set up:

TRL and Scale of set up: This demo is considered at TRL 5 with two types of algal reactors set up: one commercial horizontal reactor (600L) and one custom-made vertical reactor (2000L). The reactors used are already at their full-scale. Commercial applications would only use a higher number of the tested reactors.

Research line and priority:

This demo solution is linked to Nutri2Cycle research line 5 (RL-5: Novel animal feeds produced from agro-residue) and is one of the shortlist priority solutions i.e. sub-research line 12 (Floating wetland plants grown on liquid agro-residues as a new source of proteins).

Description of the demo:

The current demonstration study investigates microalgae-based valorisation of nutrient-rich digestate, a liquid agro-residue and co-product of the anaerobic digestion (AD) process, for production of protein-rich biomass and as an alternative treatment pathway to land application of digestate. More specifically, regions of North-West Europe which are characterized by local surplus of nitrogen fertilizers are in need of such alternative processing strategies. Microalgae can actively recycle nutrients present in digestate to cultivate microalgae in the presence of (sun)light and without the need of arable land. However, the challenging raw digestate characteristics – high concentrations of nutrients (ammonium), dark colour (turbidity) and high viscosity – may cause microalgal growth inhibition due to toxicity, limited light penetration and non-homogenous distribution of algal cells within the medium respectively. A series of physico-chemical pre-treatment techniques including centrifugation-dissolved air floatation (within AD facility), paper-filtration, dilution and acidification (with inorganic phosphorus solution) are applied to improve the properties of digestate. A mixed consortium of Desmodesmus sp. and Chlorella vulgaris are cultivated on the paper filtered digestate (PFD) under non-axenic conditions in a 3-litre lab-scale photobioreactor and 3000-litre pilot-scale facility. In lab-scale studies, under 10% (v/v) PFD without acidification condition, a biomass productivity of 0.1 g/L/day DW at nitrogen (N) and phosphorus (P) uptake of 16.5 mg N/day and 0.24 mg P/day are observed, respectively. The additional acidification step enhances the N-uptake and P-uptake to 28.5 mg N/day and 1.2 mg P/day yielding a final biomass productivity of 0.09 mg/L/day DW with protein content of 67% (w/w). Furthermore, preliminary pilot-scale trials performed in two batches under varying digestate loading conditions (2% and 5% v/v) presents a similar biomass productivity of 0.08 mg/L/day but higher N-uptake rate of 3600 mg N/day and P-uptake of 180 mg P/day.

How it addresses the Nutri2Cycle goals:

In this demonstration study, both lab- and pilot-scale investigations are performed to exhibit the microalgae-AD technology. A factory-processed liquid fraction of digestate of plant and food-waste origin, rich in N and P content, are pre-treated with a paper (bag) filter to improve its properties for microalgae cultivation – reduction of viscosity, turbidity and increasing the light penetration capacity. These improvements enable active and maximal recycling of soluble nutrients (especially N and P) from digestate to produce protein-rich biomass. During this process, C is sequestered by utilizing carbon dioxide as an inorganic carbon source for promoting algae growth and for pH stabilization in a 3-litre lab-scale photobioreactor and 3000-litre pilot-scale facility.

Infographic

This project has received funding from the European Union’s Horizon 2020

This project has received funding from the European Union’s Horizon 2020