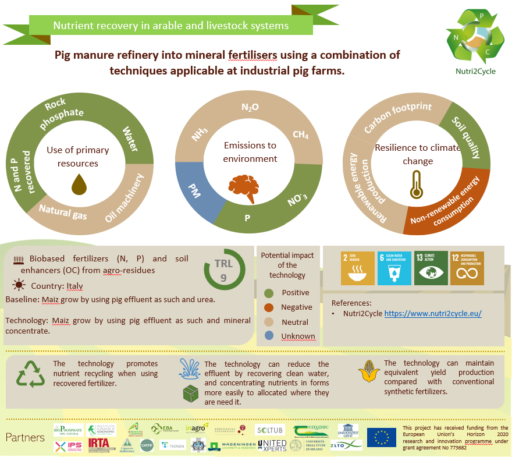

11. Pig manure refinery into mineral fertilizers by using a combination of techniques applicable at industrial pig farms

RL4: Biobased fertilisers (N, P) and soil enhancers (OC) from agro-residues

Responsible partner: University of Milan

Country: Milan, ITALY

TRL and Scale of set up:

This demo operates at a pilot-scale facility (TRL 9) consisting of sequential separation and reverse osmosis technologies. The technology mainly uses physical treatments to obtain a sustainable valorization of livestock manure by reducing effluent volume and concentrating nutrients. This solution works with the effluent of a pig farm that indicatively grows 10,000 pigs.

Research line and priority:

This demo solution is linked to Nutri2Cycle research line 4 (RL-4: Biobased fertilisers (N, P) and soil enhancers (OC) from agro-residues) and is one of the shortlist priority solutions i.e. sub-research line 7 (Pig manure processing and replacing mineral fertilizers).

Description of demo investigation:

This solution combines physical and chemical treatments in order to obtain a sustainable process of valorisation of livestock manure. The whole process aims to close CNP loops, since the obtained by-products can be reused in agriculture as fertilizers and soil quality enhancers. The full-scale plant is situated in northern Italy and works with the effluent of a pig farm that indicatively grows 10,000 pigs. The solution exploits sequential separation processes, i.e. screw press separation, vibrating screens and three stages of filtration (Reverse Osmosis, RO), in order to reduce livestock effluent volume removing nitrogen. This technology can work on different substrate, though in this case is applied on swine effluent. There are three end-products:

- Permeate: clean water, which can be disposed in superficial water bodies.

- Solid fraction: that contains high quantity of organic matter and some nutrients, that can be exploited in field as organic fertilizers,

- Liquid fraction concentrate: containing most of nutrients, it can be used in full field and the over dose exported.

This solution allows farmers to have more livestock heads thanks to the nutrient recovery and export. The solid fraction is be used in field in pre-sowing and the concentrate is used partly on topdressing and partly exported from the farm.

The separation process goes through three main steps:

- Screw press separator: this first separation divides most of the solid fraction from a semi/liquid one which goes to the second step.

- Vibrating screen separation: this stage removes some solid fraction, which is added to the one coming from step 1 and a liquid fraction that goes to the third step.

- Series of RO stages: the permeate, i.e. clean water, is disposed in superficial water bodies, while concentrate is used in field.

While solid/liquid separation of livestock effluent is a well-known technology, studies on further concentration of the liquid fraction and its use in field are insufficient.

How it addresses the Nutri2Cycle goals:

This solution is very interesting for closing CNP loops:

• N: some nitrogen (about 15%, mainly in organic form) is in the solid fraction, used as pre-sowing fertilizer/soil improver. Some other remains in Liquid fraction concentrate and finally the exceeding part is exported from the farm as ammonium sulphate.

• C: most of the organic matter in the effluent is in the solid fraction, that can be used as such or after composting in pre-sowing in field. Increasing the quantity of organic matter in soil has a double positive effect of increase fertility and reduce carbon emission thanks to carbon sequestration in the soil.

• P: most of this element is supposed to be found in the solid fraction, the speciation study and the NMR analysis on P compounds greatly improve our knowledge about availability and pathways of this element.

Infographic

This project has received funding from the European Union’s Horizon 2020

This project has received funding from the European Union’s Horizon 2020