6. Trial potato growing with refined pig manure fractions

RL3: Tools, techniques & systems for higher-precision fertilization

Responsible partners: ZLTO, Wageningen University, Ghent University

Country: Reusel (Postelsedijk 15), THE NETHERLANDS, Ghent BELGIUM

TRL and Scale of set up:

This demo is considered to be at TRL 5-6 and has been set up at field plots with a large potato grower at farmland. This trial involves using refined pig manure fractions (liquid fraction after anaerobic digestion and scrubbing salt) of one pig farmer with a pig manure processing plant to grow potatoes without the use of chemical fertilizers at one potato farm.

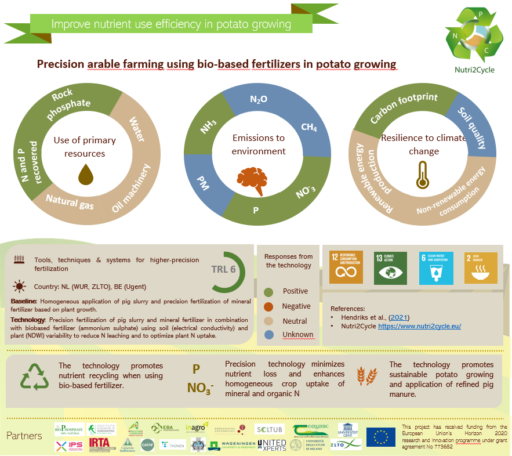

Research line and priority: This demo solution is linked to Nutri2Cycle research lines 3 and 4 (RL-3: Tools, techniques & systems for higher-precision fertilization, RL-4: Biobased fertilisers (N, P) and soil enhancers (OC) from agro-residues) and is under two shortlist priority solutions i.e. sub-research line 21 – Field assessment of precision arable farming using bio-based fertilizers in potato growing (LL73) and sub-research line 7 – Pig manure processing and replacing mineral fertilizers (LL43).

Description of the demo:

This demo investigates the effect of using bio-based fertiliser products in combination with precision agriculture. Different bio-based fertilisers are tested next to mineral fertilisers considering the safe and practical use of these fertilisers for potato growing. The effect on N use efficiency, potato yield and quality, and costs versus revenues are investigated. This demonstration trial is a collaboration between a pig farmer, a company specialised in processing pig manure, and a potato grower, all with the aim to contribute to close the nitrogen loop. The manure of the pig farmer is processed into the following bio-based fertiliser products: liquid and solid fraction of the digestate, scrubbing salt and K-concentrate. The demo set-up is divided into three parts: (i) an incubation experiment to analyse the mineralisation rate of the bio-based fertiliser products, (ii) a pot-experiment to measure the nitrogen fertilizer replacement value, and (iii) a field-trial to test bio-based fertiliser products with different levels of refinement.

(i) The mineralisation rate of three bio-based fertiliser products (liquid fraction of the digestate, scrubbing salt, and K-concentrate) is tested under controlled conditions at the laboratory. To analyse release and mineralisation rate, N – incubation tests are performed over a span of 120 days. For this, four replicates of each product are tested against mineral fertilizer (CAN) at every 20 days. The initial dosage of 170kg N/ha is applied at a WFPS of 50%.

(ii) In a pot-experiment under semi-controlled conditions in an open tunnel, the fertiliser replacement value is derived. This value indicates how well a bio-based fertiliser product is able to replace mineral fertiliser. All three products are tested against mineral fertiliser (CAN and KCl). To draw a yield curve, pots with 0, 20, 40, 70 and 100% of the advised amount of N or K fertiliser are prepared, which corresponds respectively to 0, 62, 124, 217, 310 kg N/ha and 0, 53, 106, 186, 265 kg K2O/ha. The performance of the bio-based fertiliser products is tested with 40% of the advised amount of N fertiliser (in the case of the liquid fraction of the digestate and scrubbing salt) or K fertiliser (in the case of K-concentrate) to get a clear distinction between the different products.

(iii) In the field, six treatments and three repetitions are set-up. The treatments are randomized within the field and received the following products: (i) no mineral and no organic fertiliser (0-treatment), (ii) liquid fraction (based on the recommended amount of N), (iii) liquid fraction and manure, (iv) scrubbing salt, (v) scrubbing salt and manure, and (vi) mineral fertiliser and manure. Except the 0-treatments, all fields receive 100% of the advised amount of N fertiliser (310 kg N/ha). The fields are monitored during the growing season, and soil -and leaf samples are tested for N content. The under-water yield per plot is assessed and therefore, the effect of using different refinement levels of pig manure could be assessed. In the end, the remaining amount of N in the soil is measured per plot to analyze the N leaching.

How it addresses the Nutri2Cycle goals:

Processing pig manure leads to nutrient and carbon recovery. This field-trial contributes to the Nutri2Cycle goal by replacing mineral N fertiliser for bio-based fertiliser products, which stimulates closing the N loop. Besides, this field-trial also stimulates the N use efficiency by using precision fertilisation techniques.

Infographic

This project has received funding from the European Union’s Horizon 2020

This project has received funding from the European Union’s Horizon 2020