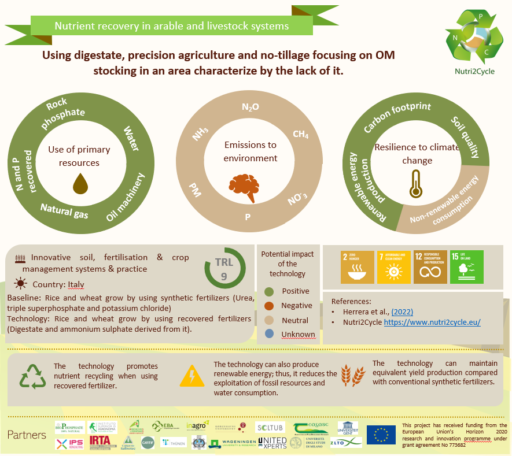

4. Using digestate, precision agriculture and no-tillage focusing on OM stocking in an area characterized by the lack of it

RL2: Innovative soil, fertilisation & crop management systems & practices for enhanced N, P efficiency and increased soil OC content

Responsible partner: University of Milan

Country: Milan, ITALY

TRL and Scale of set up:

This demo is operating at a full-scale anaerobic digestion (AD) facility (TRL 9) in Northern Italy. This innovation-solution is a compound interaction of technologies to process wastewaters and agro/food industrial waste. It includes anaerobic digestion, ammonia stripping system, bio-fertilizer and soils enhancers production, nutrients recycling, precision farming and minimum tillage tools applied effectively in rice crop.

Research line and priority:

This demo solution is linked to Nutri2Cycle research line 2 (RL-2: Innovative soil, fertilisation & crop management systems & practices for enhanced N, P efficiency and increased soil OC content) and is one of the shortlist priority solutions i.e. sub-research line 1 (Practices for increasing soil organic matter content).

Technical set up of the demo:

This demonstration case is based on full-scale anaerobic digestion (AD) plant located in Lombardy (Northern Italy), which integrates a stripping system effectively, with precision agriculture and no-tillage practices. The plant treats about ~70,000 t year-1 of wastes (mainly sewage sludge of urban wastewater), producing digestate and ammonium sulphate exploited as amendment and fertilizer in field, respectively. Biogas production is transformed into a combined heat power (CHP) unit for producing heat and electric energy that is largely used for the operational needs of the facility. By recovering nutrients from organic waste, this study presents a solution for closing CNP loops not only at nutrient level but also by using internally the co-products (i.e. heat and electricity) generated representing savings in energy consumption, linked directly with a lower environmental impact due to less reliance in traditional (fossil) energy sources. This system decreases the Total Ammonia Nitrogen (TAN) level in the reactor, avoiding or reducing ammonia inhibition during the AD, while at the same time produce ammonium sulphate (NH4)2SO4, which is mainly exploited as a valuable fertilizer in the field. Experimental rice and wheat fields are placed close to the anaerobic digestion plant, covering an overall area of 2 ha; they are divided into nine parcels of around 600 m2, where three treatments (digestate fertilization, mineral fertilization and a non-fertilized control) are tested in triplicate. In order to minimize the impact on the environment, field management and agricultural operations are performed following the principles of minimum tillage and precision agriculture.

How it addresses the Nutri2Cycle goals:

As full-scale anaerobic digestion (AD) facility coupled with a stripping system and CHP unit, it addresses to close the C-N-P loops by recovering nutrients from different sources of organic wastes and utilizing co-products like digestate and ammonium sulphate as a bio-fertilizer, while the main product biogas is converted in electricity and heat to be reused in the system. Minimum tillage and precision farming techniques are as well integrated to improve health condition in the soil, particularly organic matter.

Infographic

This project has received funding from the European Union’s Horizon 2020

This project has received funding from the European Union’s Horizon 2020